Enercon Industries, the global leader in induction cap sealing technology, has launched two new induction cap sealers – the Super Seal™ Pro and Super Seal™ Max – across Europe.

Building on the proven performance and reliability of the popular Super Seal™ Touch range, these latest models introduce the next evolution of Enercon’s innovative sealing technology.

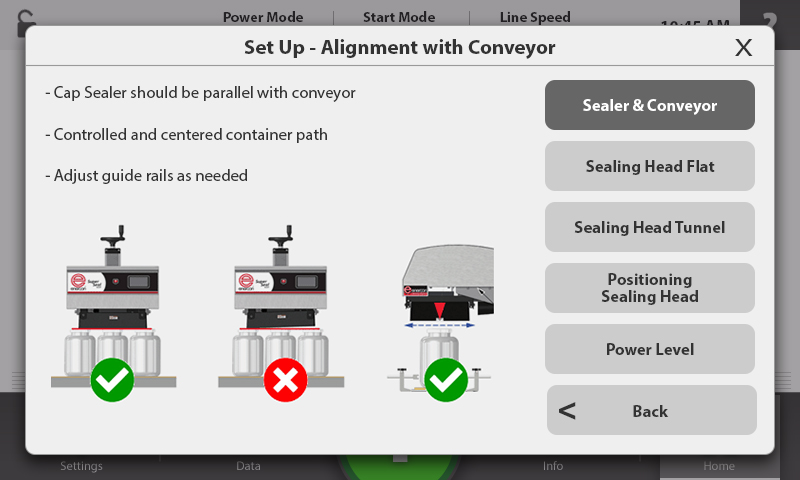

Designed to deliver maximum sealing power and unparalleled operational control, they bring powerful new features that make induction sealing setup, operation, and troubleshooting easier than ever before.

Learn more about these machines and their new features in this short video:

Key upgrades include:

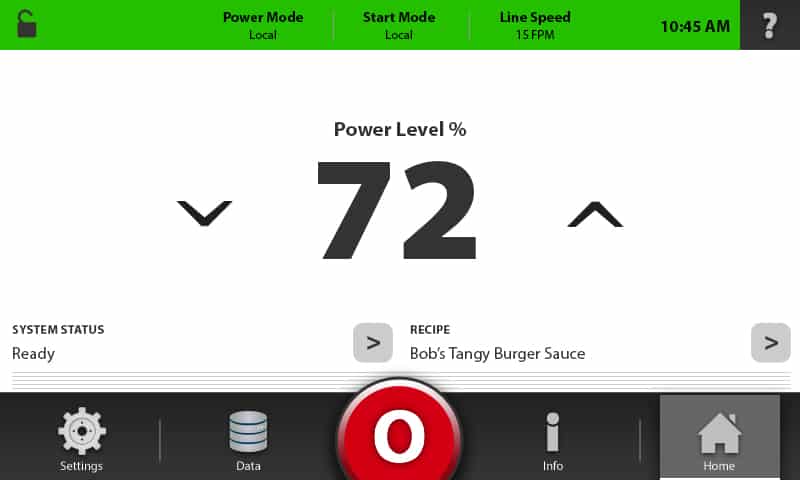

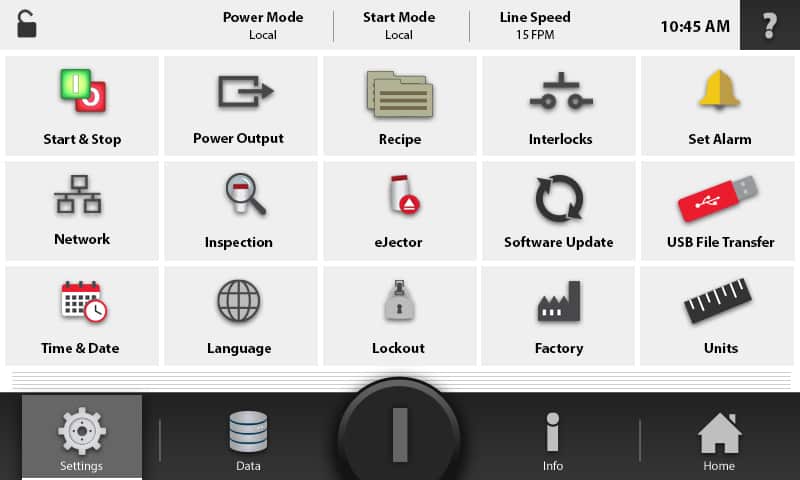

- Larger 7” touchscreen – offering simplified system navigation and new tools to assist with set-up, operation, and troubleshooting.

- External USB port – for quick software updates, and easy export of event, maintenance, and fault logs.

- Advanced fault logging – automatically captures critical operating data before, during and after an event for faster technical support.

- Wider network compatibility – now supports nearly all standard protocols for remote control and monitoring.

- Improved recipe management – store up to 50 recipes for quick line changeovers.

- Multi-level user security – ensuring controlled access for different operator levels.

Compact and air-cooled, these innovative sealers are suited to a wide range of industries, including food, beverage, pharmaceuticals, cosmetics, automotive, household goods, dairy, and chemicals. They accommodate various container shapes, sizes, and materials, sealing cap diameters from 20mm to 150mm.

- The Super Seal™ Pro runs at speeds of up to 40 metres per minute, making it ideal for medium to high-speed production lines.

- The Super Seal™ Max is engineered for the fastest and most demanding lines, operating at speeds of up to 100 metres per minute.