Enercon has the widest range of Induction Heat Sealing Coils or Sealing Heads of any manufacturer of Induction Cap Sealing equipment.

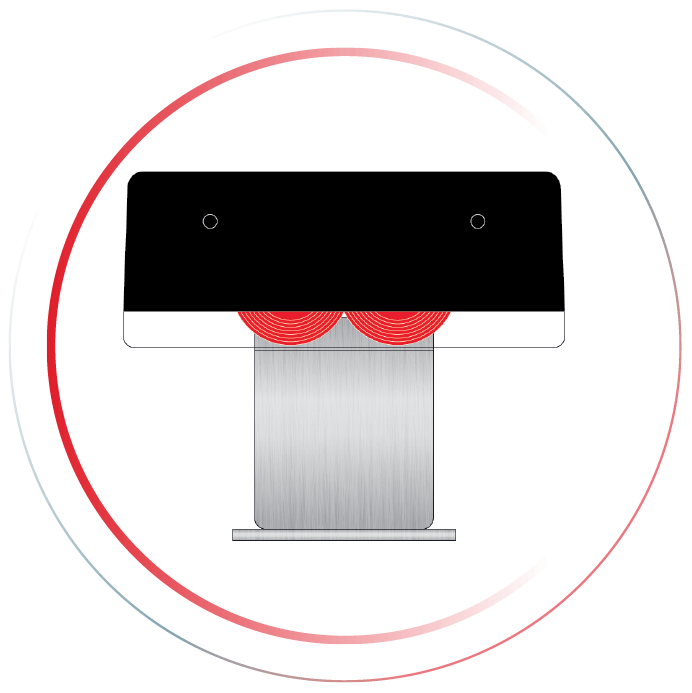

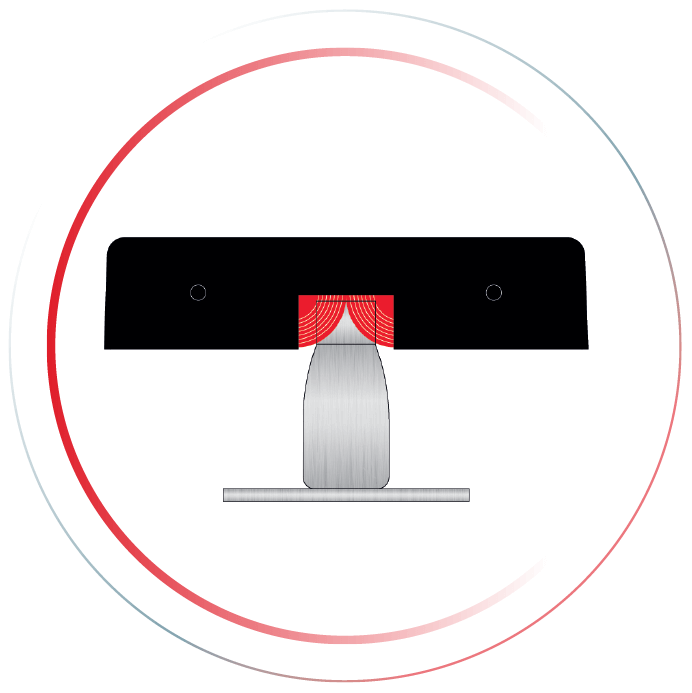

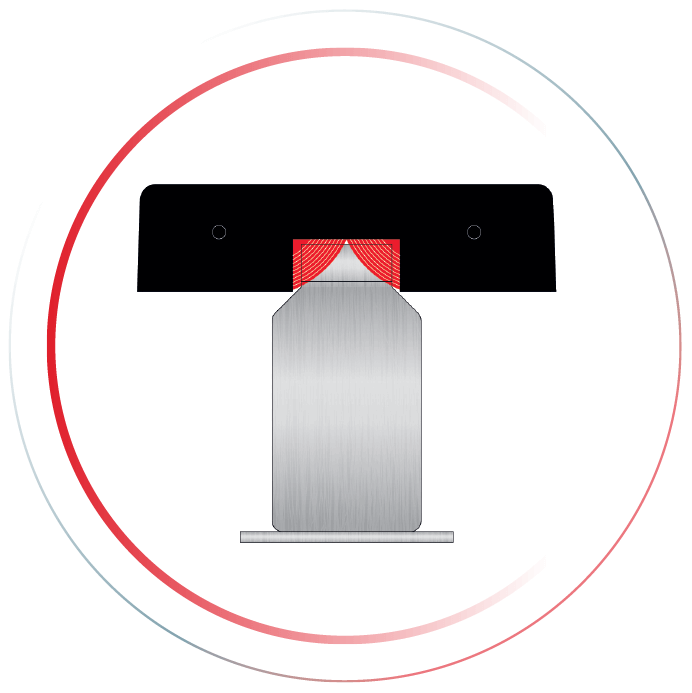

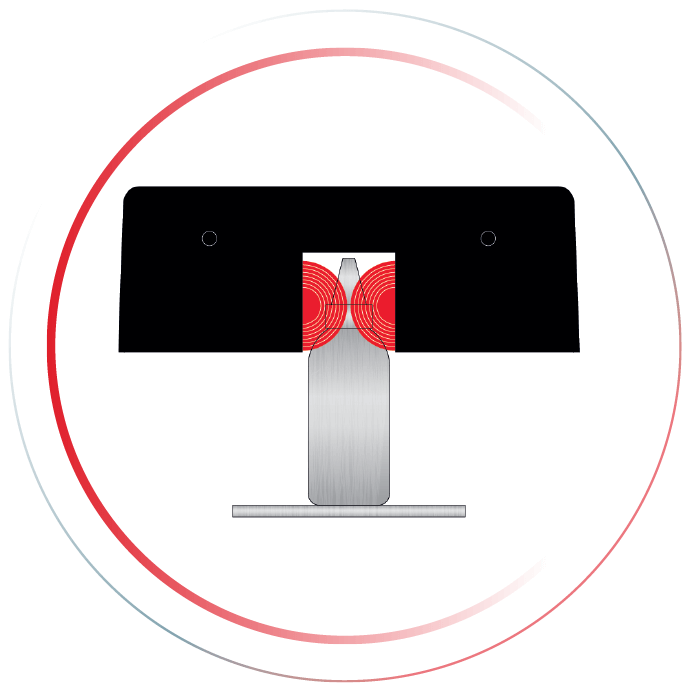

Enercon has two coil design types, each with a number of variations, to ensure the perfect coil is available for the size and type of your container and cap for your application to deliver perfect, consistent seals.

Tunnel coils facilitate higher throughputs, while flat coils offer the flexibility to seal caps from 15mm to 150mm. The Deep Tunnel Coil is used for conical, spouted and other shaped caps.

The ‘All-in-One Universal Coil’ is a variation of the Flat Coil. It is available with the Super Seal™ range and Super Seal™ Touch. This flat sealing head can be pivoted to accommodate various applications. Capable of sealing containers with cap diameters ranging from 15mm to 150mm, it is ideal for packagers who seal a variety of containers and offer the highest degree of sealing versatility.

Packagers often don’t realise that the efficiency of the sealing operation depends on the design of the sealing head. The secret to creating fast, efficient, consistent sealing is the energy transfer into the foil liner.

The Enercon Induction Coils perform to the same sealing standard whether it’s one or a whole row of caps underneath the induction coil.

Contact us

At Enercon we take into consideration the cap diameter and height, the line speed and the type of foil liner needed for the application before recommending the sealing head.

Our technical experts will match your requirements to one of our unique coils to help you achieve maximum productivity with minimum energy requirements.

Everyday our Induction Cap Sealing technology is trusted to seal over 200 million containers in Europe alone.

Case Studies

EXTENDED SHELF LIFE

“Enercon’s machines are the only induction sealers we can use to seal our gourmet culinary sauces because of the different style cap. We are also able to change the sealing heads very easily, which allows us to seal different sized products without losing production time.”

STRONGER SEALS

“Enercon has created a unique tunnel coil that allows for even distribution of energy over the neck of the container to achieve the perfect seal without overheating”

EXTENDED SHELF LIFE

GlaxoSmithKline was struggling to hermetically seal an oval-shaped Horlicks container with a ‘snap-on’ cap. The company contacted Enercon Industries for their expert advice and a solution.