Prolong the life of your machine and proactively prevent disruptions to packaging lines with Enercon’s Preventative Maintenance Package.

Preventative Maintenance Package

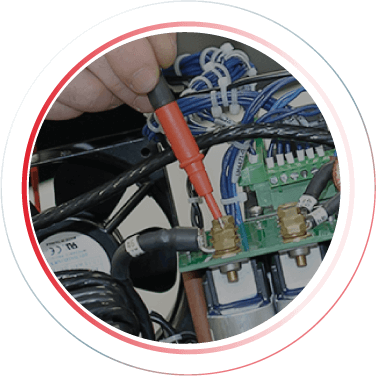

This customisable programme combines onsite service and assistance from an experienced Enercon engineer, along with operator training to ensure optimum output from your equipment over its entire life cycle. Plus, you’ll receive discount on spare parts.

By ensuring that your induction sealer is operating effectively, you can reduce energy consumption, help prevent downtime, extend the life of the equipment, and receive maximum return on your investment.

A Preventative Maintenance Package will be tailored to your specific requirements and could include: