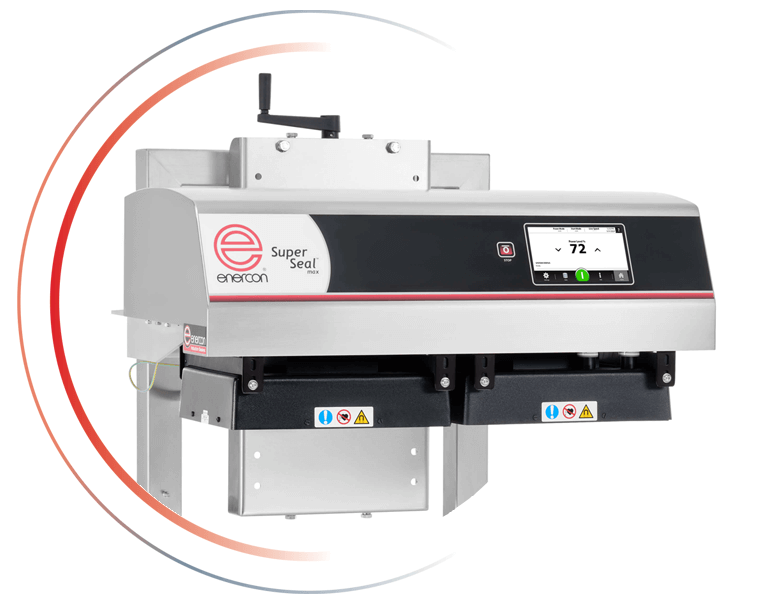

Our Inline Induction Cap Sealers

Enercon cap sealers are compact, air-cooled, easy to set up and operate and are fully compliant with all UK and European regulations.

Our induction cap sealers give customers repeatable and reliable sealing at the lowest possible cost of ownership, delivered through high levels of reliability, low maintenance costs and reduced overheads.

Whether you wish to seal small or large quantities, there’s an Enercon induction sealer for you.

Several factors will influence your choice of sealer, including production volume and line speed, your product, its container, the size, shape and height of your cap and the induction foil you use.

For all our inline machines we offer many different variations of our flat, tunnel and all-in-one induction coils to ensure the perfect coil is available for the size and type of your container and cap. They deliver perfect, consistent seals from 15 – 150mm.

Available with a robust fully-adjustable stainless steel stand (suitable for food and clean environments) they sit above your line requiring no connection other than an electricity supply.

You can get an indication of which sealer is correct for you by using the form to the right.

Specify your machine

Case Studies

EXTENDED SHELF LIFE

“GlaxoSmithKline was struggling to hermetically seal an oval-shaped Horlicks container with a ‘snap-on’ cap. The company contacted Enercon Industries for their expert advice and a solution.”

PREVENTS CONTAMINATION

“The coffee manufacturer Beanies Flavour Co, was in need of a cleaner sealing method for the production of its flavoured instant coffee. For this particular need, induction cap sealing proved to be a more effective alternative to glue.”

STRONGER SEALS

“The wine company Zipz Inc was in need of an alternative method to conduction to seal single serve glasses of wine. The company switched to induction cap sealing to solve the problem of too many leakers.”